Bio-based renovation

Bovensmilde

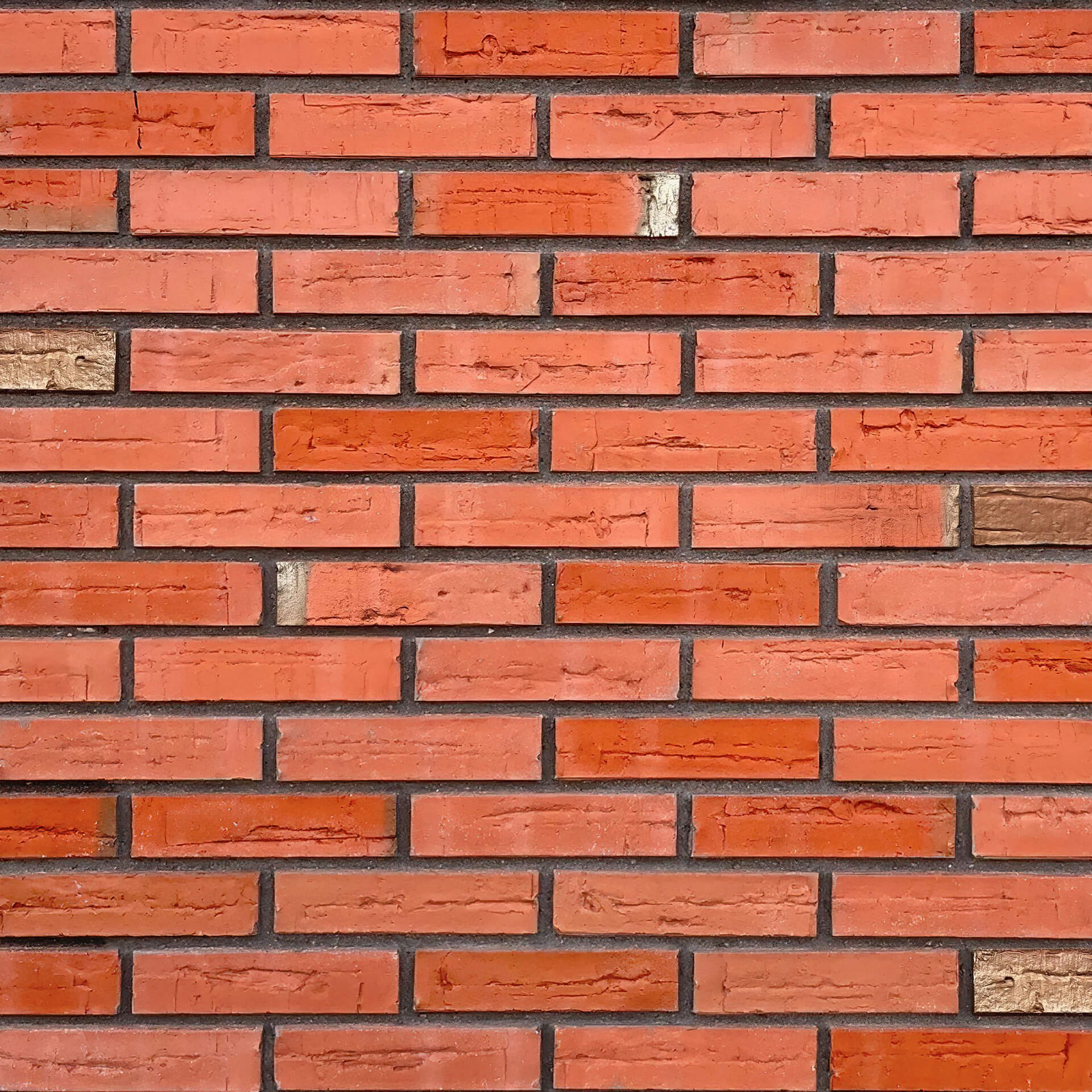

How do you make a 1960s home future-proof without losing its character? In Bovensmilde, an innovative approach was chosen: renovation with bio-based materials. These are building materials based on renewable raw materials such as wood and paper. For the brick plinth, HJK Architects and Actium deliberately chose our Dinkelsteen®. The facing brick is sustainable in production and, thanks to its slim format, can be used on the existing foundation, even with thicker insulation.